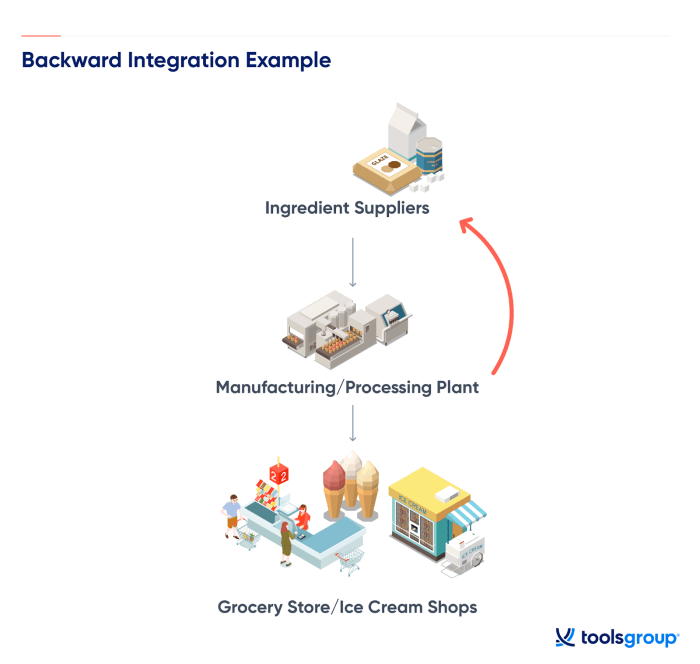

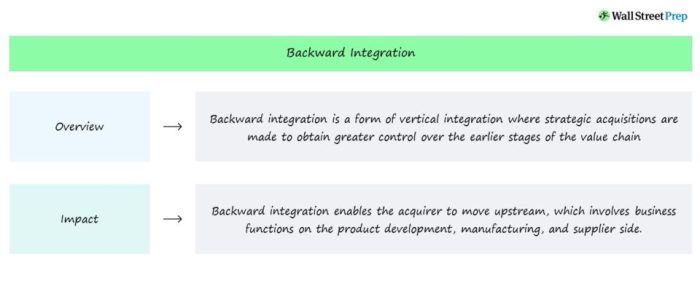

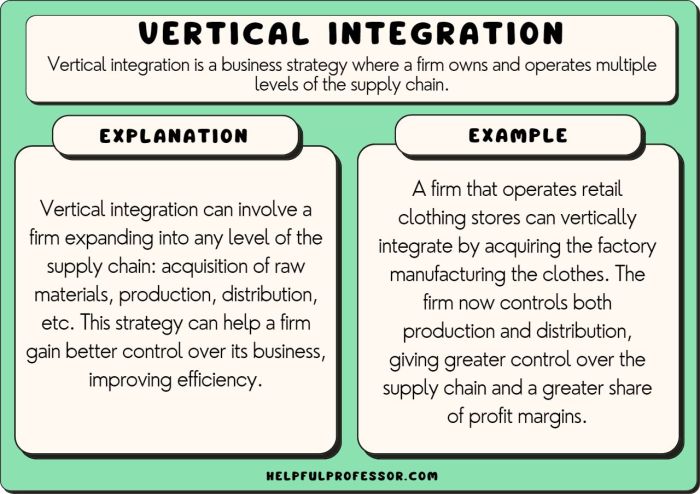

Which of the following best illustrates backward vertical integration? Backward vertical integration, a strategic business move, involves acquiring ownership or control over suppliers or other businesses in the supply chain. This in-depth analysis explores the concept, benefits, challenges, and real-world examples of backward vertical integration, providing valuable insights for businesses considering this strategy.

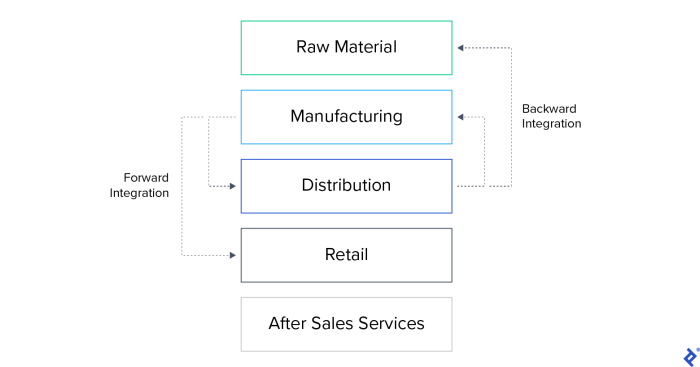

Backward vertical integration differs from forward vertical integration, which focuses on acquiring control over distributors or customers. By gaining control over suppliers, businesses aim to secure access to raw materials, reduce costs, improve quality, and increase efficiency.

Backward Vertical Integration

Backward vertical integration is a business strategy in which a company acquires or develops its own suppliers or sources of raw materials. It involves moving backward in the supply chain to gain greater control over the production and distribution of its products or services.

Backward vertical integration differs from forward vertical integration, which involves acquiring or developing distributors or retailers to gain control over the distribution and sale of products or services.

Benefits of Backward Vertical Integration

- Increased control over supply chain:Backward vertical integration allows companies to control the quality, cost, and availability of their raw materials or supplies.

- Reduced costs:By eliminating intermediaries, companies can reduce the cost of acquiring raw materials or supplies.

- Improved quality:Companies can ensure the quality of their raw materials or supplies by producing them themselves or sourcing them from reliable suppliers.

- Increased flexibility:Backward vertical integration gives companies the flexibility to adjust their supply chain quickly in response to changes in demand or market conditions.

Examples of companies that have successfully implemented backward vertical integration include:

- Apple, which designs and manufactures its own hardware and software

- Amazon, which owns its own fulfillment centers and logistics network

- Tesla, which manufactures its own electric vehicles and batteries

Challenges of Backward Vertical Integration

- High upfront investment:Backward vertical integration can require a significant upfront investment in capital and resources.

- Increased complexity:Managing and operating additional businesses or functions can increase the complexity of a company’s operations.

- Potential loss of focus:Backward vertical integration can lead to a loss of focus on a company’s core competencies.

To mitigate these challenges, companies should carefully consider the following factors before implementing backward vertical integration:

- Strategic fit:The strategy should align with the company’s overall business objectives.

- Market conditions:The market should be stable enough to justify the investment and complexity.

- Financial resources:The company should have sufficient financial resources to support the investment.

- Operational capabilities:The company should have the necessary operational capabilities to manage and operate the acquired or developed businesses.

Steps for Implementing Backward Vertical Integration

- Planning:Develop a detailed plan that Artikels the objectives, scope, and timeline for the integration.

- Acquisition or development:Acquire or develop the necessary suppliers or sources of raw materials.

- Integration:Integrate the acquired or developed businesses into the existing supply chain.

- Monitoring:Monitor the performance of the integrated businesses and make adjustments as needed.

Best Practices for Backward Vertical Integration, Which of the following best illustrates backward vertical integration

- Focus on core competencies:Backward vertical integration should complement the company’s core competencies and not detract from them.

- Partner with suppliers:Collaborate with suppliers to ensure quality and reliability.

- Use technology:Leverage technology to streamline operations and improve efficiency.

- Monitor market conditions:Continuously monitor market conditions and adjust the strategy accordingly.

Answers to Common Questions: Which Of The Following Best Illustrates Backward Vertical Integration

What are the key benefits of backward vertical integration?

Enhanced control over supply chain, reduced costs, improved quality, and increased efficiency.

What are the potential challenges of backward vertical integration?

High investment costs, increased complexity, and potential loss of flexibility.

Can you provide an example of a company that has successfully implemented backward vertical integration?

Apple’s acquisition of component suppliers to ensure quality and reduce costs in its iPhone production.